Welcome to Midway Rotary Die Solutions!

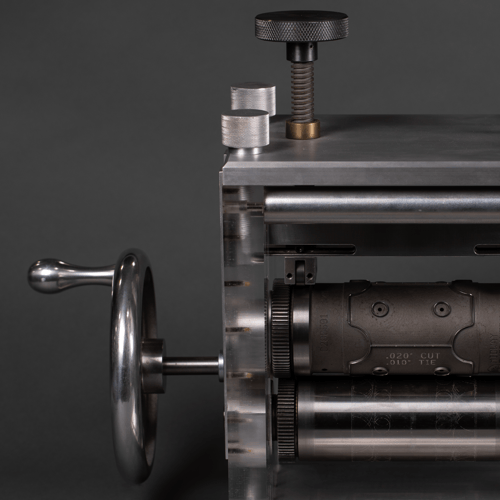

Midway Builds Premier Dies Designed To

What We Offer

World Class Service.

We're dedicated to providing all of our clients support for what they need.

Consistency.

Our dies are built to cut the thickest materials & run again and again.

Innovation.

We're the diemakers people come to when others turn them away.

We Make Dies For Around The Globe!

Midway proudly crafts our dies onsite at our facility in Williamston, MI just outside of Lansing! Midway also has a Retool facility in St. Louis, MO!