Precision rotary dies, built for uptime.

Midway Rotary Die Solutions (MRD) keeps production lines running with engineers, machines, and services. We provide exceptional solid and flexible tooling for the converting industry.

Williamston, Michigan

Purpose-built facility with dedicated grinding and hardening cells.

50 years

Heritage in rotary die innovation

ISO program

Documented tolerances & traceability

98% on-time

Most orders ship early

Products

MRD product families

Rotary dies and tooling engineered for uptime, accuracy, and unparalleled performance.

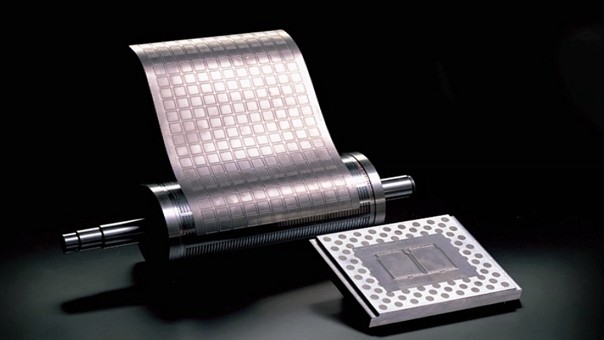

Solid Rotary Dies

Through-hardened dies engineered for long runs, tight tolerances, and predictable resharpening.

Flexible Pinnacle Die® by Tsukatani — AP and NP types

Tsukatani Flexible Pinnacle Die® program (AP/NP) for labels, films, foams, and cushioning materials across North America—built on the Atlas Flex heritage.

Gears

Precision gears designed to maintain registration and minimize backlash.

Process

How we work

A five-step design process to ensure customer success exceeds expectations

Application discovery

We review substrates, liners, adhesives, and press data to baseline the die design.

Engineering review

Create die-designs to achieve accurate part size, control waste, maximize tool life

Precision machining

Advanced CNC centers with cutting-edge CAD/CAM software deliver consistent finishes and accuracy

Validation & documentation

Every tool ships with inspection reports, recommended pressure settings.

Lifecycle support

Same-day responses, rapid resharpen, and on-press troubleshooting.

Differentiators

Why converters choose MRD

Superior engineering, Industry Expertise, and Technical Support to exceed project expectations

Engineering-first partnership

We collaborate with converters and OEMs to remove uncertainty before the die is on press.

Reliable Performance

All orders are tracked and documented throughout the process to ensure on press production

Responsive lifecycle services

Dedicated service coordinators keep resharpening and repairs on schedule.