Anvil programs

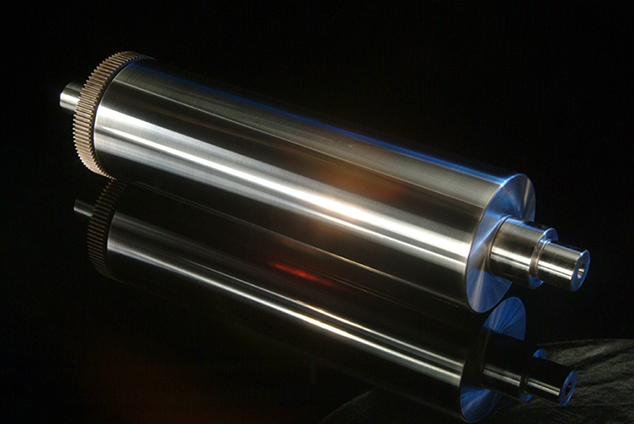

Precise High Rockwell polished anvils provide flawless, consistent cutting

Each anvil ships with documented Rockwell, TIR, and taper specs so adhesive stacks stay in tune throughout the run.

Anvils

62-64 Rockwell keeps the cutting die wearing first while a smooth, critical anvil surface complements the die so quality parts stay consistent.

Key specifications

- TIR and taper within 0.0002"

- Surface finish better than 16 µin Ra (0.4 µm, ISO N5)

- Up to 16" diameter

- Max length of 60"

- Stepped, straight, vacuum anvils available

Highlights

- Shipped with mating die setup notes

- Lifecycle tracking to align resharpen intervals

- Regrind programs available for long-term cost control

Request a tailored quote

Share your substrate specifics, liner, adhesive, and desired run window. We will respond with a recommended steel selection and tolerance stack.

Request a quoteNeed engineering support first? Email midwaycsr@midwayrotary.com with your application details.

FAQ

Frequently asked questions

What tolerances do you hold on MRD anvils?

Runout is held to <=0.0001" TIR with surface prep tailored to your liner. Detailed inspection reports accompany each shipment.

Can you reverse engineer existing anvils?

Yes. Send a sample or detailed prints and we will produce a matched replacement.

Can you refurbish anvils?

We inspect, polish, and regrind anvils as part of our lifecycle service programs to keep tooling aligned.