Photocutter operations

Model 9000 Photocutter setup & support

Clamp the Photocutter to a sturdy bench, attach the catch tray, and plug into a grounded 110 V outlet to start running photo, badge, or keycard jobs with confidence.

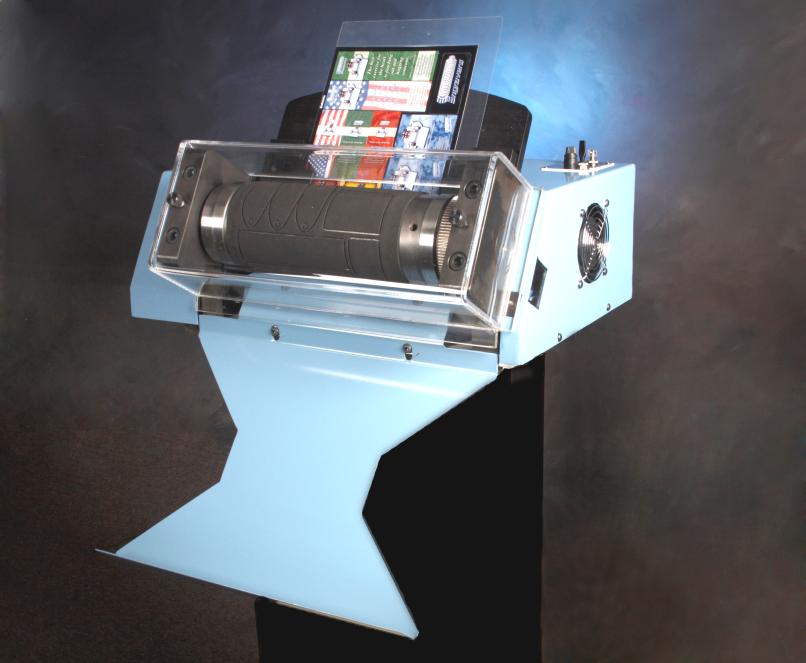

Model 9000 Photocutter

The Model 9000 Photocutter is a benchtop rotary cutter that clamps to the edge of a sturdy table, accepts installed tooling, and runs on a grounded 110-volt outlet. Catch trays, left and right guides, and fine pressure adjustments make it easy to process photos, keycards, or even basic rotary press trials while keeping the operator protected behind a clear safety cover.

Key specifications

- Self-contained 225 lb machine that mounts at the table edge with a bolt-on catch tray

- Grounded 110 V plug with illuminated on/off switch and safety interlock on the clear cover

- Left- and right-hand guides plus adjustable stop pockets keep cuts centered on photos or keycards

- Four pressure bolts accept a 3/8" Allen wrench for incremental die pressure adjustments

Highlights

- Handles photo trimming, badge/keycard work, or light rotary press duties with the same platform

- Ships with tooling installed and documented instructions so trial sheets can run immediately

- Front cover removes for quick belt tension checks, lubrication, or stop-pocket alignment

- Supported by MRD service for retooling, troubleshooting, and replacement lubricants

Request a Model 9000 Photocutter quote

Tell us the photo sizes, ID badges, or small press sheets you cut most and we will confirm tooling, guide, and catch tray setups that keep the machine running smoothly.

Request Photocutter quoteNeed install help or the operating manual? midwaycsr@midwayrotary.com can send instructions or schedule service.

FAQ

Frequently asked questions

How do I adjust cutting pressure on the Photocutter?

Disconnect power, remove the two retaining screws, and lift off the clear cover. Tighten each of the four pressure bolts equally with the supplied 3/8" Allen wrench, using only small turns before retesting with a sheet. If the machine stalls, back the bolts off and snug them again in equal increments.

What routine maintenance does the Model 9000 need?

Apply the included high-pressure lubricant across the gear teeth, re-grease journal block bearings with fresh lubricant if they are removed, and add a few drops of graphite lubricant to each felt bearer wipe monthly. Keeping these points lubricated maintains smooth rotations.

What safety precautions should operators follow?

Operate the machine only on a stable surface that supports 250 pounds, plug it into a grounded 110 V circuit, and keep the clear protective cover installed so the kill switch stays engaged. Always disconnect power before adjustments and use two people when lifting the 225 lb unit or removing tooling.