Downloads

We’ll select the right Pinnacle series for you based on your materials, liner, and press.

Tsukatani partnership

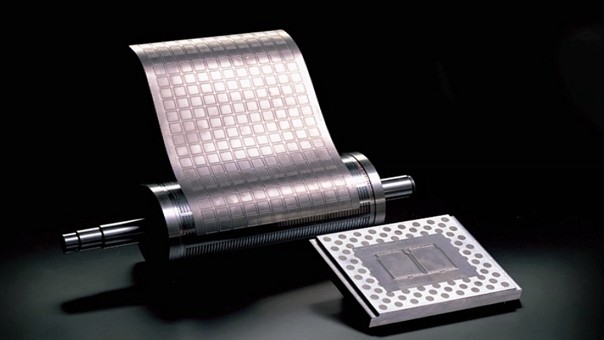

Flexible Pinnacle Die® and NP Pinnacle® are products of Tsukatani Hamono Mfg. Co., Ltd., offered in North America through Midway Rotary Die Solutions.

Manufactured with Tsukatani’s proprietary sharpening technology for sharp, stable cutting even on complex shapes— built on the Atlas Flex heritage now supported by MRD.

.png)

Atlas Flex

Heritage

Tsukatani

Pinnacle Die®

Manufactured with Tsukatani’s proprietary sharpening technology for sharp, stable cutting even on complex shapes, backed by Midway Rotary Die Solutions for North American converters.

Share your substrate specifics, liner, adhesive, and desired run window. We will respond with a recommended steel selection and tolerance stack.

Request a quoteNeed engineering support first? Email midwaycsr@midwayrotary.com with your application details.

FAQ

Yes. Provide the magnetic cylinder serial or inspection sheet and MRD will match die pitch, undercut, and gear profile.

Not currently; we recommend new builds to keep edge geometry consistent. We do share handling and storage precautions so edges stay protected between runs.

Standard AP type Tsukatani builds run around HRC50. Specify hard-type AP for ~HRC68 and add DLC or titanium coatings when you need extra wear resistance.

Follow Tsukatani handling notes: protect sharpened edges, keep magnetic particles away, use light rust prevention when storing, and keep dies flat on a magnetic plate or protective sheet. Full precautions are included in the Tsukatani downloads.

Specify Tsukatani’s TS coating option (non-adhesive monomolecular coating) when adhesive or ink pick-up is likely to improve cleanliness and ease of wash-up.

Yes. AP type covers common paper and filmic liners; Midway will tune relief and edge prep for your liner range.

Thick foams, cushioning materials, and double-sided tapes where low cutting pressure and straight edges are critical.

Up to 0.2 mm height difference between edges for combined kiss- and through-cuts (per Tsukatani spec).

Downloads

We’ll select the right Pinnacle series for you based on your materials, liner, and press.